A contribution to the global academic research blog series

written by Anna Freund

Ph.D. Candidate at Corvinus University of Budapest, Hungary

Expert in Food Industry 4.0

I recently participated in the ‘Experimental Learning, Flow & Serious Gaming’ Ph.D. course delivered by Dr. Zoltan Buzady at our university. This was the first time I came across the FLIGBY simulation as part of the learning process. In the following, I summarize some intellectual aspects and connections between my own research area, Industry 4.0 effects on the Food Industry, and the FLow theory.

My research deals with the signs of Industry 4.0’s impact on food safety. I want to raise awareness in the interest of both, the academic community and also the internal (e.g. managers) and external (e.g. costumers, state) stakeholders of a food industry company.

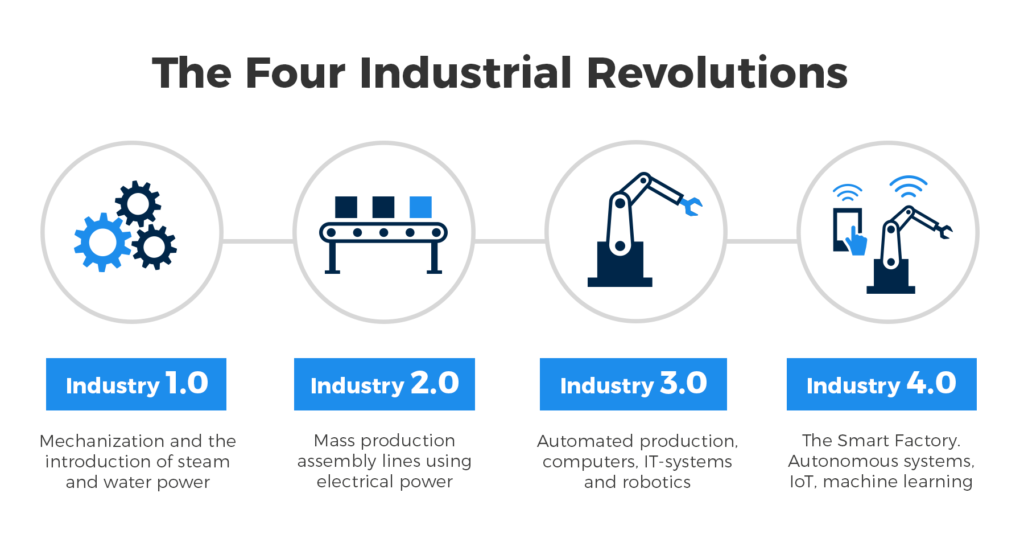

Industry 4.0 optimizes the computerization of Industry 3.0

When computers were introduced in Industry 3.0, it was disruptive thanks to the addition of an entirely new technology. Now, and into the future as Industry 4.0 unfolds, computers are connected and communicate with one another to ultimately make decisions without human involvement.

https://www.forbes.com/sites/bernardmarr/2018/09/02/what-is-industry-4-0-heres-a-super-easy-explanation-for-anyone/?sh=78d88b2a9788

My main research question focuses on the methodology of tracing and tracking, which both have significant importance on the area of quality assurance, in particular in the food industry (Tian, 2017; Tse, 2017). From an economic and social point of view, we are now in the age of Industry 4.0, which has a major impact on the whole economy. A big part of Industry 4.0 can be realized in the automation of data transfer. We can say that excellent food safety conditions can be supported by real-time transmission, analysis, and interpretation of data characterizing products and processes (Bibi et al., 2017; Carpenter and Wyman, 2017; Bottani and Rizzi, 2008).

Flow theory can be connected to my research at this point. Especially because the above-mentioned signs are researched by me using qualitative research methodology. This part of the research aims to be an exploratory research process.

I see a good connecting point to my field, but rather from a marketing/sales point of view. Within the research process, interviews and observations are conducted at companies and case studies are written based on the gained data. As a summary of the experiences I can tell, that the investments in connection with Industry 4.0 solutions (sensors, IoT (software and hardware), CPS (cyber-physical-systems), robots…etc.) are the most expensive ones. These decisions of the leaders have a high impact on the lives of their company. Because of this big weight, it would be valuable for them too, to gain experiences how to make better decisions.

Thus, based on my course experience, I know can fully recommend the FLIGBY, Flow-leadership simulation serious game, to the leaders who deal with decision and core business question.

It clearly helps them to “pre-play” in the game, ie. before taking the risk in real-life context.

The interviewees of my Ph.D. thesis research are general managers and top leaders. because they have the most comprehensive views about all operation of the observed company. Thus I think they are the key targets of developing a holistic approach to implementing complex business solutions via their own departments and employees.

I’d also want to share here my own personal learning experiences gained on this course. During the 1st round of FLIGBY, I decided to “play from my heart”, which means that I didn’t want to use a strategy, which doesn’t fit my personality. I really wanted to test myself, what kind of results can be achieved by me playing with the so-called “original settings”.

After having finished the 1st round a meeting came with the course leader to analyze our performance. This step is one of the most valuable ones, it opens the eyes, it contributes to highlighting the most important factors/skills, which influence our performance. Since this was a group meeting it was also useful to listen to the experiences of the other participants.

As a next step, the members can continue the game with their 2nd full game round. Here I’d recommend choosing another strategy, which isn’t the same as the first, original one was. In my specific case, it turned out after the group meeting, that I don’t show enough empathy to my management team. Also, I discovered that giving feedback could be more important in my decisions.

So I decided to use this more soft way of work during the game. In a conclusion, I can say, that unfortunately not all measured results of the virtual company I was managing have increased, but some of my soft skills have improved.

Now, I assume that within the 3rd game round some balance of the “original” and the “soft skill-based” settings can lead to more sustainable success.

I’d use my story as a promotion to the leaders I meet, because I truly believe that this point of view can contribute to handling such difficult and important decisions, like the Industry 4.0 investments.

On the other hand as a researcher, I’ll use the knowledge received from the course to improve my analytical skill in connection with analyzing the interviews I conducted previously.

To understand the decision-making of the leaders the FLOW theory and so the FLIGBY simulation (Marer&Buzady&Vecsey, 2015, Buzady, 2017) seems to be a good offer.

As an example, I’d show the situation of a GM from the dairy industry. He is a leader of a milk producer company. He told me about the planned investments within their corporation. Then, I asked him about the motivation behind the decisions. I assume that not only cost-efficiency and manufacturing difficulties are behind the choice of digital solutions. I could understand it from the interview, that human issues are also a very strong influencing factor. Not only the amount of the workforce is critical, but also the resistance of the employees can cause difficulties to implement Industry 4.0 solutions.

As a researcher, I could then use the FLOW theory to analyze my interviewees based on this knowledge. After having examined the 29 leadership skills of the examined leader I could state some recommendations which could contribute to the success and long term competitiveness of the examined company. In this specific case, there is a strong engagement of the leaders, they are representatives of the Industry 4.0 based investments. To convince the staff, he could focus on the main 4 skills (Feedback, Balancing skill, Strategic thinking, and Applying personal strengths), highlighted within the FLIGBY simulation.

I would use this knowledge offered by the course to understand the mainly qualitative parts of my research easier and to have some deeper information about the decisions, which are introduced by the interviewees.

Please contact Anna Freund, PhD Candidate, Expert in Food Industry 4.0.

References:

1. Bibi, F., Guillaume, C., Gontard, N., &Sorli, B. (2017). A review: RFID technology having sensing aptitudes for food industry and their contribution to tracking and monitoring of food products. Trends in Food Science &Technology, 62, 91-103. https://doi.org/10.1016/j.tifs.2017.01.013

2. Bottani, E., &Rizzi, A. (2008). Economical assessment of the impact of RFID technology and EPC system on the fast-moving consumer goods supply chain. International Journal of Production Economics, 112(2), 548-569. https://doi.org/10.1016/j.ijpe.2007.05.007

3. Buzady, Z. (2017). Flow, leadership and serious games–a pedagogical perspective. World Journal of Science, Technology and Sustainable Development. https://www.researchgate.net/publication/315915982_Flow_leadership_and_serious_games_-_a_pedagogical_perspective

4. Marer, P., Buzady, Z., Vecsey, Z. (2015): Missing Link Discovered.

https://www.amazon.com/Missing-Link-Discovered-Csikszentmihalyis-Flow-Leadership-ebook/dp/B01N1SAC9Z/ref=sr_1_1?dchild=1&qid=1611312687&refinements=p_27%3APaul+Marer&s=books&sr=1-1

5. Carpenter, G. &Wyman, O. (2016). Food manufacturing – Are you ready for Industry 4.0? Marsh Report, Marsh and McLennan Companies, UK https://www.marsh.com/uk/insights/research/food-manufacturing-are-you-ready-for-industry.html (latest download: 16.01.2021)

6. Tian, F. (2016, June). An agri-food supply chain traceability system for China based on RFID &blockchain technology. In 2016 13th international conference on service systems and service management (ICSSSM) (pp. 1-6). IEEE. https://doi.org/10.1109/ICSSSM.2016.7538424

7. Tse, D., Zhang, B., Yang, Y., Cheng, C., &Mu, H. (2017, December). Blockchain application in food supply information security. In 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM) (pp. 1357-1361). IEEE.https://doi.org/10.1109/IEEM.2017.8290114

8. DOMBROWSKI, U. & WAGNER, T. (2013). Mental Strain as Field of Action in the 4th Industrial Revolution. https://doi.org/10.1016/j.procir.2014.01.077